Let’s be honest — when it comes to audio quality, no one wants static, buzzing, or that frustrating “hiss” that ruins the immersive experience. If you’re all about that premium sound and you’ve got yourself some YYAudio RCA connectors, knowing how to solder them properly can make all the difference.

But don’t worry! Even if you’re not a professional electrician, soldering RCA connectors isn’t rocket science. It’s actually a satisfying DIY project that ensures your sound system is wired for success (pun intended!).

In this guide, we’ll show you how to solder YYAudio RCA connectors step-by-step, ensuring you’ll have a sturdy, long-lasting connection that’ll deliver flawless audio for years to come.

What Are YYAudio RCA Connectors and Why Are They Important?

An RCA connector, sometimes known as a phono connector, is that small but mighty piece of hardware responsible for transmitting audio and video signals. Originally developed in the 1940s (yes, it’s been around that long), these connectors are still widely used in home audio and entertainment systems today.

If you want to avoid annoying crackles and weak sound output, soldering your YYAudio RCA connectors is essential. Why? It creates a solid and durable bond between your cables and connectors, ensuring your audio flows smoothly without interruptions. Plus, by DIY soldering, you ensure every connection is custom-fitted to your gear, which can significantly enhance sound quality.

So, if you’re tired of amateur connections letting you down, let’s dive into the soldering process. Don’t worry, we’ve got your back — no explosions, just crisp sound ahead!

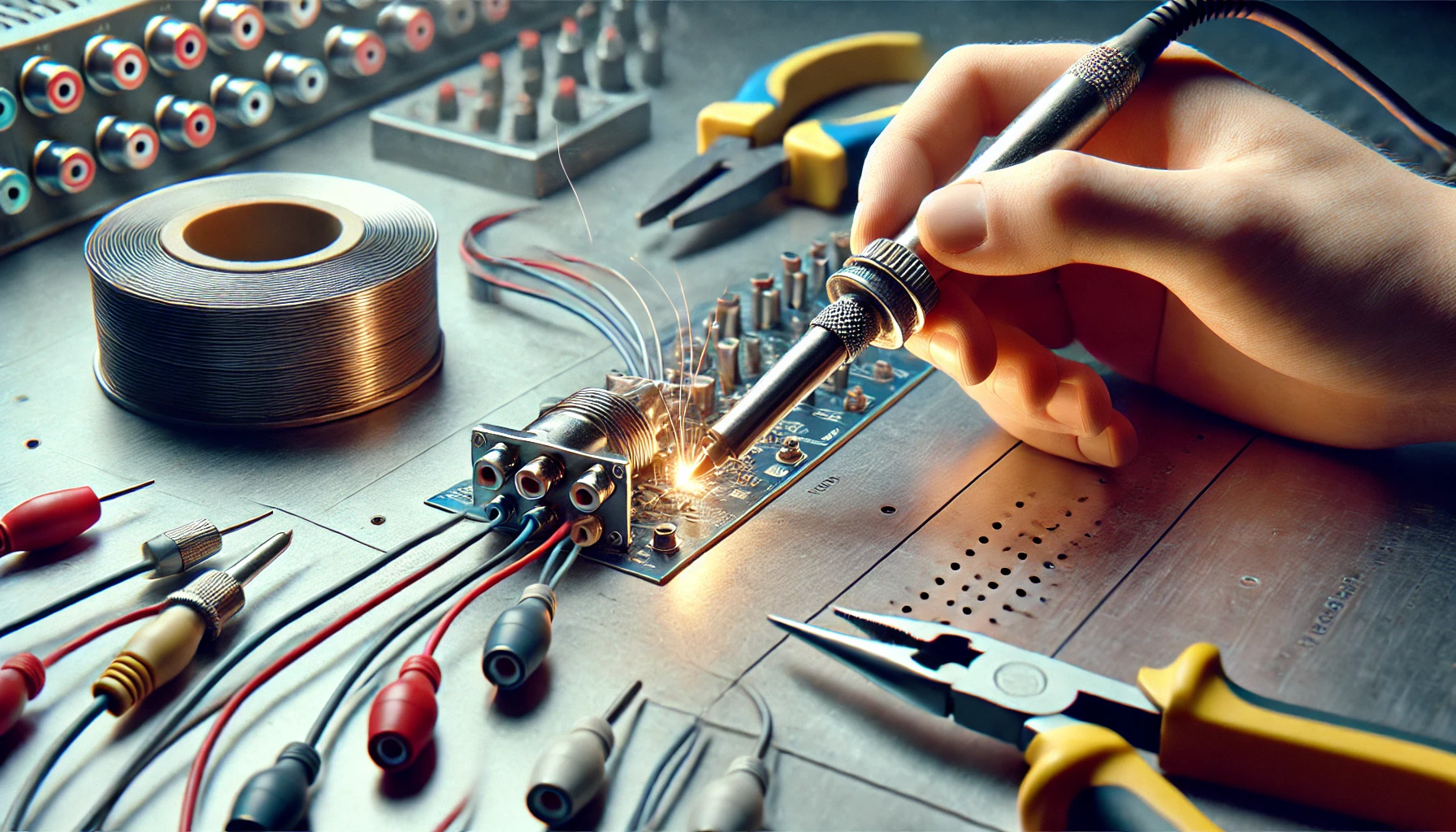

Tools and Materials You’ll Need to Solder an RCA Connector

Before you start, gather your tools. Trust me, having everything on hand will save you from running around the house mid-solder (safety first, right?).

Essential Tools:

- Soldering Iron: Ideally, go for one with adjustable temperature control, around 25 to 40 watts.

- Solder Wire: We recommend 60/40 rosin-core solder — a reliable and easy-to-use option.

- Wire Cutters and Strippers: For trimming and preparing your wires for the soldering process.

Additional Materials:

- Heat Shrink Tubing: This will protect your newly soldered joints, keeping them safe and insulated.

- Helping Hands Tool: A third hand always comes in handy (see what we did there?). This tool stabilizes the cable while you work.

- Damp Sponge: For cleaning your soldering iron tip between steps, ensuring a smooth solder job.

Once you’ve gathered these materials, it’s time to roll up your sleeves and get into the fun part: the soldering!

Preparing the YYAudio RCA Connector for Soldering

It’s prep time! Before the soldering action begins, you need to prepare both the cable and the YYAudio RCA connector for the perfect union.

Step-by-Step Process:

- Disassemble the RCA Connector: Start by unscrewing the outer shell of the YYAudio RCA connector to expose the soldering points. Keep these parts in a safe spot — they tend to roll away!

- Strip the Cable Wires: Using your wire strippers, carefully remove about 1/4 inch of insulation from the ends of the cable, exposing the inner wires. Be gentle; we’re aiming for clean, unbroken wires.

- Tin the Wires: Now it’s time to “tin” the wires, which means applying a bit of solder to the exposed copper ends. This will help the solder flow more easily when we attach it to the connector, creating a stronger bond.

Tip: If you’ve ever tried to wrap a gift with crumpled paper, you’ll appreciate how tinning makes things neat and manageable!

Soldering the YYAudio RCA Connector: Step-by-Step Guide

Now we’re getting into the heart of the project. Here’s how to solder your YYAudio RCA connector like a pro (or at least close enough that your sound system won’t judge you).

Step 1: Heating the Soldering Iron

Plug in your soldering iron and give it a few minutes to heat up. You’re looking for around 350°C (660°F), which is the sweet spot for this job. Trust me, patience here pays off — trying to solder with a lukewarm iron is like trying to toast bread with a flashlight.

Step 2: Apply Solder to the RCA Pin

Take the center wire (the signal wire) and hold it in place on the RCA connector pin. Then, gently apply the soldering iron to both the wire and the pin. After a moment, touch the solder wire to the junction — the solder should flow smoothly and create a strong bond.

Step 3: Solder the Ground Wire

Next, it’s time to attach the ground wire. This is the shielding or outer wire, and it needs to be soldered to the outer ring of the RCA connector. Follow the same process as before — heat, apply solder, and let it cool.

Step 4: Inspect and Test the Connection

Before you celebrate your soldering victory, check for any weak joints or excess solder that could cause a short circuit. Give it a gentle tug — if nothing moves, you’re golden!

Common Mistakes to Avoid When Soldering RCA Connectors

Soldering may seem simple, but even the best of us can slip up. Here are some common mistakes and how to avoid them:

- Cold Solder Joints: These happen when the solder doesn’t fully melt, leading to weak connections. To avoid this, make sure your iron is hot enough and apply heat for long enough.

- Too Much or Too Little Solder: Finding the right balance is key. Too much solder can lead to short circuits, while too little leaves you with fragile connections.

- Overheating the Cable: Excessive heat can melt the insulation or damage the cable. Keep the soldering time brief and efficient.

Tips for a Professional Finish

Want your RCA solder job to look (and perform) like it was done by a pro? Here are a few finishing touches:

- Heat Shrink Tubing for Protection: Once everything is soldered and cool, slide heat shrink tubing over the joints. Apply heat (a hairdryer or heat gun works) to shrink it down and secure your connections.

- Proper Cable Management: Keep things tidy! Secure your cables and connectors to prevent strain and damage over time.

- Testing the Connection: Once everything is reassembled, test your setup to ensure smooth sound transmission. No one likes silence in their audio system (unless it’s intentional).

Benefits of Properly Soldered RCA Connectors

What’s the reward for all your effort? A flawless audio experience. Properly soldered RCA connectors give you:

- Improved Audio Quality: Say goodbye to interference and hello to crystal-clear sound.

- Longer Lifespan for Your Equipment: Solid connections protect your equipment from wear and tear.

- Elimination of Audio Interference: A well-soldered connection minimizes static and hum, ensuring your listening experience is top-notch.

Conclusion

And there you have it! You’ve just learned how to solder a YYAudio RCA connector like a seasoned DIY enthusiast. With the right tools, a little patience, and a steady hand, you can ensure your audio setup stays high-quality for years to come.

So, what are you waiting for? Grab your soldering iron, put on your favorite playlist, and get soldering! Don’t forget to drop us a comment below with your experiences or any questions. Happy soldering!